Methods turning lathe screw.

There are several methodof turning thread on a lathe

1 The conventional method

The conventional method is a method of movement threading with feeds (additional incision depth / depth of cut), upright / using the cross slide.

2. Method slice one side

This threading method by tilting the top of the slide and use the top slide 60 as funeral movement (depth of cut). This method is efficient for turning lathe the screw with a large size

The steps turning lathe the screw outside.

1 Prepare working drawings

Prepare working drawings and understand the dimensions of the image in accordance with the demands of work. It is important that during the turning lathe process the error does not occur

2 Prepare the cutting tools.

Several pieces of equipment that need to be prepared is

a. Flat Tool bit / ISO 6 to turning lathe the outer diameter of the screw

b. Tool bit face chamfer / ISO 2 for turning lathe face and make pingul or chamfer

c. Tool bit grooves / ISO 7 for turning lathe groove when liberators threading

d. Metric for turning lathe Tool bit threaded screw

3 lathe major diameter for outside thread

For turning lathe threaded outside diameter of the major outside screw is usually reduced by 0.2 mm, with the goal threading process occurs when built-up chip on the top of the screw, the screw outside diameter and will fit easily on the fitting time. For example, the M10 threaded turning lathe prior to threading turner diameter is 9.8 mm.

4 Make relief threaded grooves

relief or undercut grooves need to be made in order to not hit the chisel threading time on the corner / elbow on the turning lathe screw diameter and so the Shoulder time can be tight fitting with the corner / elbow

5 Set the peak spacing (pitch) desired

Adjust the pitch in accordance with the demands of the picture by looking at the table and turning the screw automatic gear lever on the gearbox feed according to the table. For example ......

6 Checking the suitability of the pitch screw

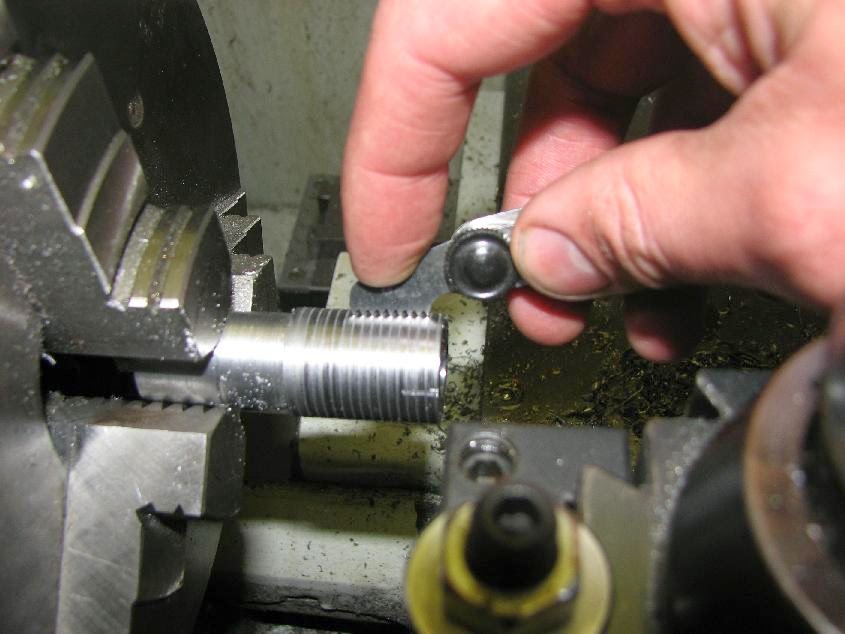

To check the suitability of the pitch is done turning lathe the screw thread with depth as thin as possible and then be checked with mall thread / pitch gauge.

7 turning thread

After the turning lathe screw can fit was done with the addition of an incision depth of 0.1 each. Fatherly finishing process adding a depth of 0.02 mm and an incision made 2-3 times at the same depth

Steps turning lathe inside thread.

In turning lathe inside thread on the same principle just different on the cutting tool and the Flat size of the turning lathe before threaded

1 Prepare working drawings

2 Prepare the cutting tools.

Cutting tools used another conduction

a. Center drill

Center drill is used to make holes in the prefix drilling holes in lathe

b. twist drill

Used to make the initial hole on the turning lathe thread

c. Tool bit ISO 8 / ISO 9

Once perforated with a twist drill is then done enlarged hole boring process with ISO 8 for through hole and ISO 9 for shoulder hole

d. Relief internal Groove tool bit

if thread not through it needs to make a groove for the release screw with a internal groove toolbit

e. Screw Tool bit inside

Used for turning lathe thread

3 Minor diameter lathe to thread

On the turning lathe screw in the hole that is the diameter of the major turner reduced pitch screw (threaded peak distance). For example Screw M16 x 2 the diameter of the hole made is 16-2 = 14 mm. and that the threaded fitting easier usually minor diameter plus 0.2 mm so that the diameter is 14.2 mm turner. to the next process in the same turning lathe with turning lathe screw threaded outside

4 Make relief threaded grooves

5 Set the peak spacing (pitch) desired

6 Checking the suitability of the pitch screw with pitch gauge

7 turning the thread until finish

Pics From :

http://www.educationlite.com/lathe-machine-operations-shoulder-turning-thread-cutting-boring/

http://firearmsdesigner.com/?p=52

nice blog on threaded fitings can u write more on shims

ReplyDeleteHi can you send me a video or explain how to read the chart of threads. Thanks

ReplyDeleteI want to share a testimony on how Le_Meridian funding service helped me with loan of 2,000,000.00 USD to finance my marijuana farm project , I'm very grateful and i promised to share this legit funding company to anyone looking for way to expand his or her business project.the company is funding company. Anyone seeking for finance support should contact them on lfdsloans@outlook.com Or lfdsloans@lemeridianfds.com Mr Benjamin is also on whatsapp 1-989-394-3740 to make things easy for any applicant.

ReplyDelete